Exploring the Benefits of Compression Fittings for DIY Home Plumbing Projects

In the realm of DIY home plumbing projects, the choice of fittings can significantly influence both the ease of installation and the durability of the plumbing system. Among various options, compression fittings have emerged as a favored choice among homeowners and professionals alike. According to a report by the National Association of Home Builders, approximately 55% of DIYers opt for compression fittings due to their simplicity and reliability.

Compression fittings provide a strong, leak-proof seal without the need for soldering or special tools, making them an ideal solution for both novice and experienced DIY enthusiasts. Moreover, a study from the Plumbing-Heating-Cooling Contractors Association indicated that the use of compression fittings can reduce installation time by up to 30%, highlighting their efficiency in various plumbing applications. As we explore the benefits of compression fittings further, it becomes evident that they not only simplify the installation process but also enhance the overall longevity of plumbing systems.

Benefits of Using Compression Fittings for DIY Plumbing Solutions

Compression fittings offer a variety of benefits for DIY plumbing enthusiasts. One of the primary advantages is their ease of installation. Unlike traditional soldering methods, which require special tools and skills, compression fittings can be connected quickly and securely using just a wrench. This makes them an excellent choice for both novices and seasoned DIYers. Additionally, compression fittings create a reliable seal without the need for heat, reducing the risk of damaging nearby materials.

Tips: When working with compression fittings, it’s essential to ensure that the pipe ends are clean and free from debris. A tight fit is crucial for preventing leaks, so take the time to measure and cut your pipes accurately. Also, avoid over-tightening the fittings, as this can damage the components and lead to failure.

Another benefit of compression fittings is their versatility. They can be used on various materials, including copper, PVC, and PEX, making them suitable for a wide range of plumbing tasks. This adaptability allows DIYers to tackle multiple projects with a single type of fitting. Remember to choose the right size fitting for your project, as this will enhance the overall effectiveness of your plumbing solution.

Tips: Keep a few common sizes of compression fittings on hand for quick repairs or modifications. Having a variety of options available can save you time and ensure you’re always prepared for unexpected plumbing issues.

Understanding the Mechanics of Compression Fittings in Home Projects

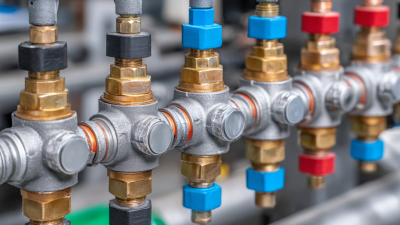

Compression fittings are essential components in DIY home plumbing projects, offering both convenience and reliability. These fittings work by compressing a ring around a pipe, creating a secure seal that prevents leaks. The mechanics behind compression fittings involve the use of a threaded nut that, when tightened, pushes the ring against the pipe. This action not only secures the connection but also provides a tight seal that can withstand varying water pressures. This simple yet effective mechanism makes compression fittings an excellent choice for those looking to tackle home plumbing tasks.

One of the key advantages of compression fittings is their ease of installation, which does not require soldering or specialized tools. DIY enthusiasts can quickly assemble and disassemble fittings, which is particularly beneficial for projects requiring frequent adjustments or repairs. Additionally, compression fittings are compatible with a wide range of materials, including copper, PVC, and PEX, making them versatile for various plumbing applications. Their ability to create reliable connections can save homeowners time and money, reducing the need for professional plumbing services while ensuring that projects remain efficient and effective.

Cost Efficiency: How Compression Fittings Save Money on Plumbing Repairs

Compression fittings are an excellent choice for DIY plumbing projects, particularly due to their cost efficiency. These fittings do not require soldering or extensive tools, making them accessible for beginners and those looking to save on labor costs. By opting for compression fittings, homeowners can significantly reduce expenses associated with traditional plumbing repairs, such as hiring professionals or purchasing specialized equipment.

When tackling a plumbing project with compression fittings, consider investing in a high-quality adjustable wrench and pipe cutter. This will ensure a clean cut on your pipes and a secure fit for the fittings. Additionally, always check for leaks after installation by turning on the water slowly and inspecting the joints. This proactive approach can save you from costly repairs down the line.

Moreover, take advantage of compression fittings in tight spaces where soldering might be impractical. They provide a reliable seal without the need for heat, making them perfect for bathroom or kitchen renovations. With the right tools and techniques, DIYers can effectively utilize compression fittings to enhance both the functionality and affordability of their plumbing systems.

Installation Tips: Ensuring a Leak-Free Connection with Compression Fittings

When undertaking DIY home plumbing projects, achieving a leak-free connection is paramount. Compression fittings are a popular choice among homeowners and professionals alike, renowned for their simplicity and reliability. According to a report from the American Society of Plumbing Engineers, over 60% of plumbing professionals prefer compression fittings due to their responsiveness to varying pipe materials and sizes. This versatility helps ensure a secure seal, minimizing the risk of leaks.

When undertaking DIY home plumbing projects, achieving a leak-free connection is paramount. Compression fittings are a popular choice among homeowners and professionals alike, renowned for their simplicity and reliability. According to a report from the American Society of Plumbing Engineers, over 60% of plumbing professionals prefer compression fittings due to their responsiveness to varying pipe materials and sizes. This versatility helps ensure a secure seal, minimizing the risk of leaks.

To install compression fittings effectively, start by cutting the pipe to ensure a clean edge. It's essential to deburr the cut end, as any rough edges can interfere with the seal. Remember to slide the compression nut and ring onto the pipe before inserting it into the fitting. Tightening the nut by hand, followed by a wrench for a firm grip, will create an even connection. A good tip is to ensure that you do not overtighten, as this can damage the fitting or the pipe, leading to leaks.

Lastly, consider testing the connection after installation. Running water through the newly fitted section ensures everything is sealed correctly and functioning as intended. Keeping a cloth nearby can help you quickly dry any spills and inspect for leaks more effectively. Following these tips can greatly enhance your experience with compression fittings, ensuring a successful DIY plumbing project.

Comparison of Compression Fittings and Soldered Pipes for Homeowners

When it comes to DIY home plumbing projects, homeowners often grapple with the choice between compression fittings and soldered pipes. Compression fittings are increasingly favored for their ease of installation and versatility. According to a 2022 report by the Plumbing Manufacturers International, approximately 68% of homeowners reported that compression fittings offered a quicker solution, allowing for repairs and installations in a fraction of the time required for soldered connections. This is particularly beneficial for those with limited plumbing experience, as no special tools or skills are needed beyond basic hand tools.

In contrast, soldered pipes provide a more permanent solution but require a steady hand and some existing expertise. The National Association of Home Builders indicates that improper soldering techniques account for nearly 20% of plumbing failures, potentially leading to leaks and increased costs in the long run. While soldered joints can handle high-temperature applications better than compression fittings, the latter are gaining a strong foothold among homeowners seeking a reliable, user-friendly option for their plumbing needs. The decision ultimately hinges on the project scope and the homeowner's confidence in their plumbing abilities.

Exploring the Benefits of Compression Fittings for DIY Home Plumbing Projects - Comparison of Compression Fittings and Soldered Pipes for Homeowners

| Feature | Compression Fittings | Soldered Pipes |

|---|---|---|

| Ease of Installation | Easy for DIY, no specialized skills needed | Requires soldering skills and tools |

| Time Required | Quick to fit and adjust | Longer due to soldering process |

| Cost | Generally more affordable materials | Higher material and labor costs |

| Flexibility | Easily adjusted and reconnected | Difficult to adjust after installation |

| Leakage Risk | Less risk if properly installed | Higher risk if soldered poorly |

| Corrosion Resistance | Good, depending on the materials | Good but can corrode over time |

Related Posts

-

How to Choose the Right Compression Fittings for Your Plumbing Needs

-

Ultimate Guide to Choosing the Right Press Fittings for Your Plumbing Needs

-

How to Choose the Right Compression Fittings for Your Plumbing Projects

-

How to Choose the Right Compression Fittings for Your Global Procurement Needs

-

Exploring the Growth of PPSU PEX Fittings Industry Trends at the 138th China Import and Export Fair 2025

-

How to Select Quick and Easy Fittings for Your Plumbing Projects