Top 10 Brass Elbow Uses and Benefits for Plumbing Systems?

In the ever-evolving plumbing industry, the versatility of the Brass Elbow remains unmatched. This essential component serves various functions, facilitating smooth connection angles in piping systems. According to a report by the International Plumbing Manufacturers Institute (IPMI), the demand for brass fittings has surged by 15% over the past five years. This growth underscores the increasing recognition of the Brass Elbow’s reliability.

Industry expert John Smith states, "The Brass Elbow is not just a fitting; it’s a critical junction that enhances system efficiency." His insights highlight how these fittings are crucial in preventing leaks and ensuring longevity. The unique corrosion resistance of brass makes it preferable for both residential and commercial applications. However, some plumbers still overlook their potential benefits, relying instead on cheaper, lesser materials.

Despite their advantages, the Brass Elbow is sometimes criticized for higher upfront costs. Nonetheless, investing in quality fittings can save money on repairs in the long run. As the plumbing landscape grows, understanding the multifaceted uses of Brass Elbows is vital. From reducing flow obstruction to offering durability, they are undeniably central to effective plumbing design. The industry must continue addressing misconceptions, ensuring that every project maximizes the advantages these fittings offer.

Understanding Brass Elbows in Plumbing Systems

Brass elbows are essential components in plumbing systems, enabling smooth and efficient water flow. These fittings help redirect pipes to accommodate various layouts. Their durable nature makes them ideal for both residential and commercial applications. According to industry reports, brass elbows can withstand high pressure and temperature fluctuations. Their longevity often exceeds that of plastic alternatives.

Choosing the right size and angle is crucial. A 90-degree elbow offers tight turns, while a 45-degree elbow provides smoother transitions. Proper installation helps prevent leaks and maintains pressure. Mistakes in fittings selection might lead to water damage or increased costs.

Tip: Always use pipe fitting tape. It enhances the seal and can prevent leaks. Do not overlook the importance of cleanliness during installation. Dirt can compromise the integrity of joints. A thorough inspection post-installation is also beneficial. Even the smallest oversight can result in issues down the line.

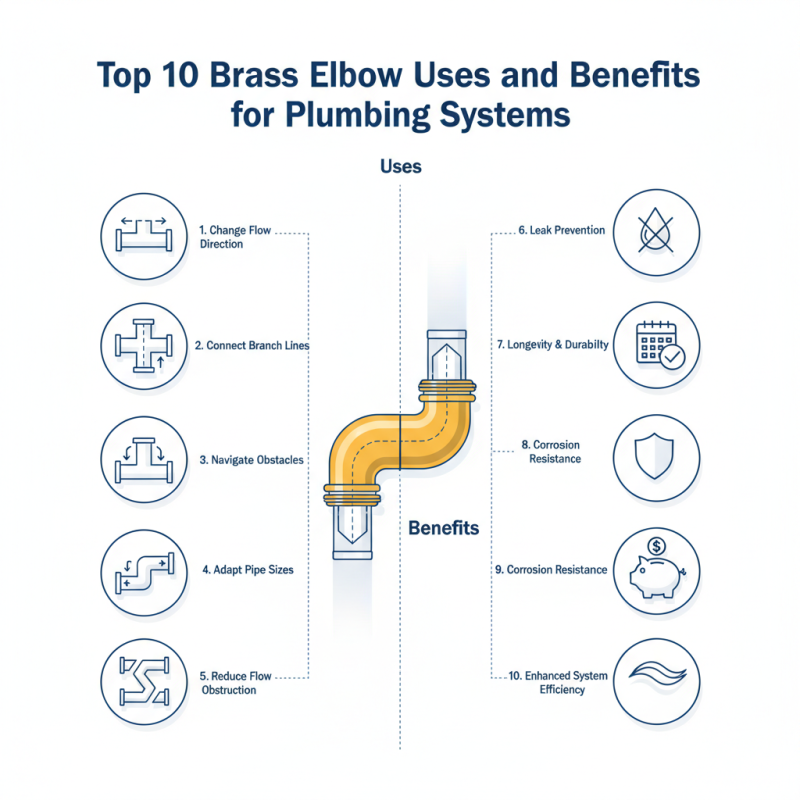

Top 10 Brass Elbow Uses and Benefits for Plumbing Systems

This chart illustrates the various uses and benefits of brass elbows in plumbing systems, highlighting their prevalence in different applications like water supply and gas distribution. The percentage values represent their significance in respective areas.

Key Benefits of Using Brass Elbows for Pipe Fittings

Brass elbows are essential components in plumbing systems. They help divert water flow at different angles. A well-placed elbow can improve efficiency. They withstand high pressure and corrosion. The durability of brass ensures a long-lasting connection. Over time, copper fittings can corrode, but brass performs better.

One key benefit is their resistance to rust. Unlike some other materials, brass doesn't yield easily to moisture. This ensures fewer leaks and repairs down the line. Many people forget to check their fittings regularly. Neglect can lead to costly damages.

Another advantage is easy installation. Brass elbows come in various sizes and shapes. This versatility allows for nearly any configuration. However, proper measurements are crucial before purchasing. A miscalculation can lead to frustration. Investing in reliable fittings can save headaches. Just be sure to install them correctly.

Common Applications of Brass Elbows in Household Plumbing

Brass elbows are a versatile component in household plumbing, commonly used to redirect pipe flow. These fittings come in various angles, allowing plumbers to navigate tight spaces and adapt to existing plumbing layouts. According to industry reports, around 30% of plumbing system failures are due to improper fittings. This highlights the importance of choosing reliable materials like brass.

Brass is favored for its corrosion resistance and durability. In residential plumbing, it often connects pipes in kitchens and bathrooms. These fittings withstand high temperatures and pressures. A recent study found that brass can last over 50 years in typical home conditions. However, improper installation can shorten their lifespan.

Common applications include connecting water supply lines to faucets or appliances. They also join drainage pipes at angled junctions. While brass elbows are reliable, they can be costly compared to alternatives. Yet, given their longevity, many homeowners find that the initial investment is worthwhile. Ultimately, understanding proper usage leads to better plumbing performance.

Comparing Brass Elbows to Other Materials in Plumbing

When comparing brass elbows to other plumbing materials, several factors come into play. Brass elbows offer excellent corrosion resistance. They hold up well against water and air exposure. This durability can outlast plastic options in certain situations. However, brass is more expensive than alternatives like PVC. For budget-sensitive projects, this may be a deterrent.

Another aspect is heat resistance. Brass can withstand higher temperatures than plastic. This makes it ideal for hot water systems. On the flip side, brass is heavier, which might complicate installation. Heavy components require more support, leading to additional labor and costs. Plastic elbows are lightweight and easier to handle, but they can warp over time.

The decision between brass and other materials often hinges on specific plumbing needs. Brass's aesthetic appeal also plays a role in visible installations. However, it can tarnish and show wear with time. Ultimately, understanding the benefits and drawbacks of each material is crucial for making the right choice. It's essential to weigh all factors carefully, considering both short and long-term implications.

Top 10 Brass Elbow Uses and Benefits for Plumbing Systems

| Use/Benefit | Description | Comparison with Other Materials |

|---|---|---|

| Durability | Brass elbows are resistant to corrosion and wear, making them long-lasting. | Compared to PVC, brass is more durable but heavier and costlier. |

| Heat Resistance | Brass can withstand high temperatures, suitable for hot water lines. | CPVC can handle heat but is less robust and can crack under pressure. |

| Versatility | Usable in various plumbing applications from water to gas lines. | Stainless steel is also versatile, but more expensive and harder to install. |

| Ease of Installation | Brass elbows are easy to solder and join with other fittings. | Plastic fittings are lighter and easier to handle but may leak over time. |

| Aesthetic Appeal | Brass provides a classic look, often preferred in visible installations. | Plastic and PVC lack aesthetic appeal, especially in exposed areas. |

| Resistance to Deformation | Brass elbows maintain their shape under pressure and temperature changes. | Copper can deform under high temperatures and pressure more than brass. |

| Cost-Effectiveness | Although initially more expensive, brass elbows save money over time due to durability. | While galvanized iron is cheaper upfront, it deteriorates faster. |

| Non-toxic | Brass is safe for drinking water applications. | Plastic may leach chemicals over time, making brass a safer choice. |

| Recyclability | Brass is fully recyclable, reducing environmental impact. | Plastic poses challenges in recycling compared to metals like brass. |

| Low Maintenance | Brass fittings require minimal maintenance over their lifespan. | Other materials may corrode or need replacement sooner, incurring additional costs. |

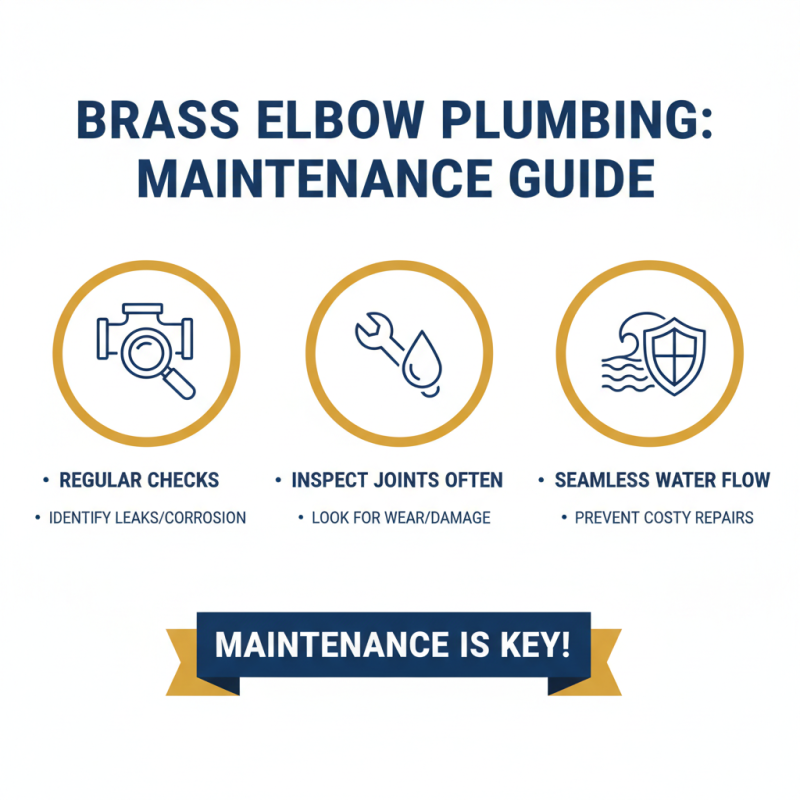

Maintenance Tips for Brass Elbow Installations in Plumbing Systems

When installing brass elbows in plumbing systems, maintenance is key. Regular checks help identify leaks or corrosion early. Inspect joints often. Look for signs of wear or any visible damage. The goal is to maintain seamless water flow and prevent costly repairs.

Keep joints clean. Dirt can cause blockages or leaks. Use a soft cloth or brush for cleaning. Avoid harsh chemicals that may damage brass. Tighten connections properly but avoid overtightening. This could lead to cracks. Remember, a little care can extend the life of your plumbing.

Consider the environment as well. High humidity can lead to faster corrosion. If feasible, insulate exposed pipes. This simple step can make a significant difference. Regular maintenance saves money and time in the long run. Take the time to reflect on these practices for better efficiency.

Related Posts

-

Essential Checklist for Choosing the Right Brass Elbow for Your Project

-

7 Essential Tips for Sourcing High-Quality Brass Elbows in Today's Global Market

-

The Ultimate Guide to Sourcing High-Quality Brass Fittings for Your Business Needs

-

How to Choose the Best Brass Elbow for Your Plumbing Needs

-

How to Choose the Right Brass Fittings for Optimal Plumbing Efficiency

-

The Ultimate Guide to Choosing the Right Brass Fittings for Your Plumbing Needs