How to Choose the Right Ball Valve for Your Industrial Needs

Choosing the right ball valve for your industrial needs is a crucial decision that can significantly impact the efficiency and safety of your operations. Ball valves are essential components in many applications, known for their reliability and excellent sealing capabilities. With various types available, each designed for specific operating conditions, understanding the important factors in selecting the appropriate ball valve becomes paramount. Considerations such as valve material, size, pressure rating, and the type of flow control required can influence not only performance but also long-term maintenance costs. In this guide, we will explore the key elements that should guide your selection process, ensuring that your choice of ball valve effectively meets the demands of your industrial environment while optimizing performance and durability.

Identifying Your Industrial Application Requirements for Ball Valves

When selecting the right ball valve for your industrial needs, it's crucial to first identify your specific application requirements. Various industries have distinct parameters such as pressure, temperature, and fluid types that can greatly influence the type of valve you choose. According to a recent market analysis by MarketsandMarkets, the global ball valve market is projected to reach $12.53 billion by 2025, indicating a growing demand for tailored valve solutions across sectors like oil and gas, water treatment, and chemical processing.

Tips: Consider the maximum operating pressure and temperature your system will endure. For example, valves designed for high-temperature applications often feature specialized materials to resist thermal expansion and maintain integrity.

Understanding the fluid dynamics is also vital. The valve material should withstand the chemical properties of the fluid being conveyed, whether it is corrosive, viscous, or contains particulates. A report by ResearchAndMarkets highlights that industries are increasingly favoring corrosion-resistant materials like PVC and various alloys.

Tips: Always refer to data sheets provided by manufacturers, which detail the compatibility of various materials with specific fluids, ensuring a long-lasting and reliable operation.

Understanding Different Types of Ball Valves and Their Features

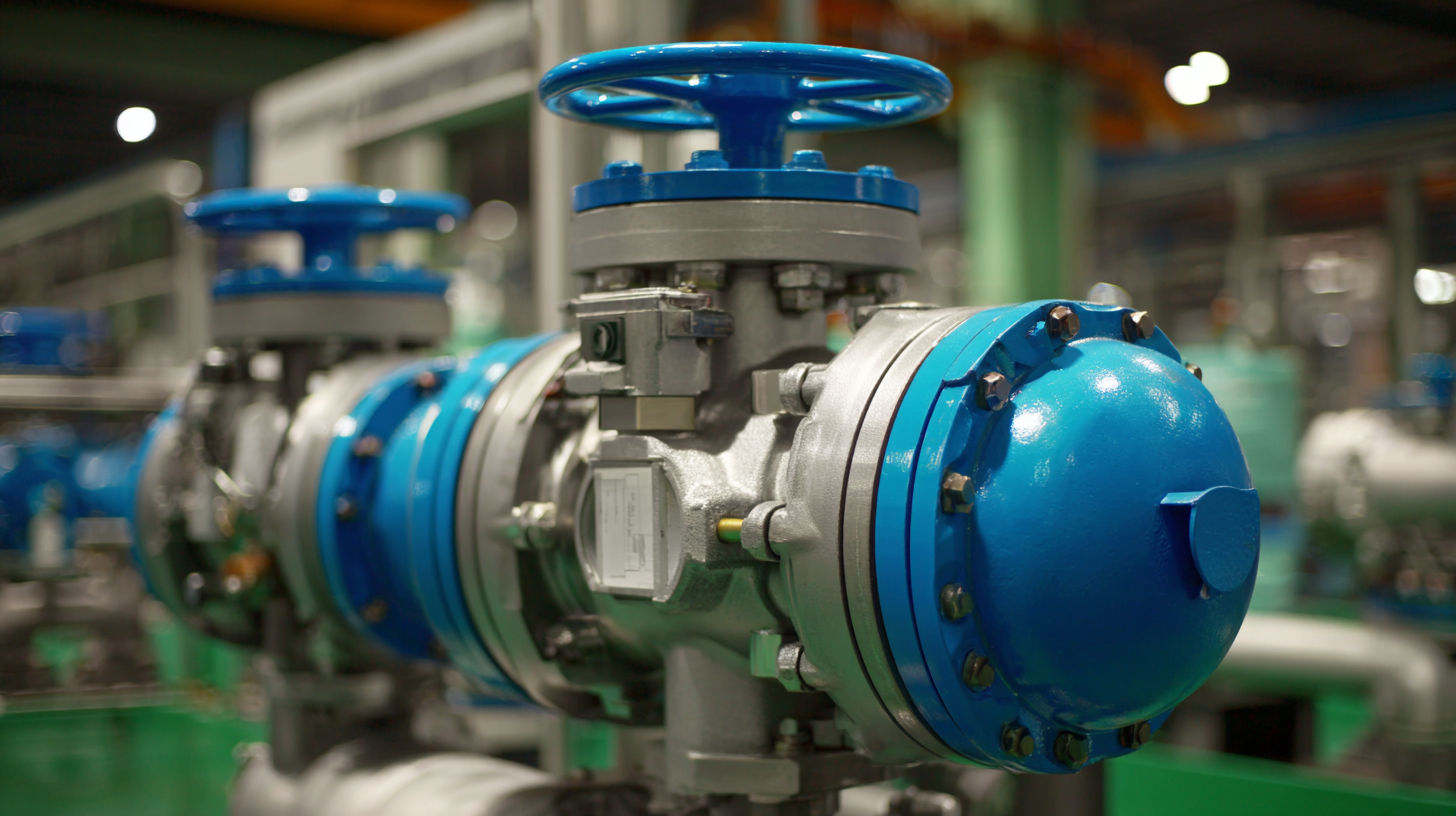

When selecting a ball valve for industrial applications, understanding the various types available is crucial. One common type is the floating ball valve, where the ball is held in place by the two seats, allowing it to move slightly to facilitate a tighter seal. This design is often favored for lower pressure applications and provides excellent sealing performance. Another type is the trunnion-mounted ball valve, which features a ball fixed in place by trunnions at the top and bottom. This configuration supports higher pressure and larger sizes, making it ideal for demanding industrial environments.

Additionally, ball valves come in different materials, affecting their performance and compatibility with various fluids. For instance, stainless steel ball valves offer superior corrosion resistance, making them suitable for environments with aggressive chemicals. In contrast, PVC ball valves are lightweight and cost-effective for less demanding applications. Understanding these types and their respective features helps industries choose the right ball valve that not only fits their needs but also ensures efficiency and safety in their operations.

How to Choose the Right Ball Valve for Your Industrial Needs

| Valve Type | Connection Type | Material | Pressure Rating (PSI) | Temperature Range (°F) | Applications |

|---|---|---|---|---|---|

| Floating Ball Valve | Threaded | Stainless Steel | 150 | -20 to 200 | Water, Gas |

| Trunnion Ball Valve | Flanged | Carbon Steel | 300 | -40 to 400 | Oil, Chemical Processing |

| Full Port Ball Valve | Union | Bronze | 150 | -20 to 180 | HVAC, Water Supply |

| Split Body Ball Valve | Welded | PVC | 75 | 0 to 140 | Chemical Handling |

Evaluating Size and Pressure Ratings for Optimal Performance

When selecting a ball valve for industrial applications, evaluating size and pressure ratings is crucial to ensure optimal performance. The size of the valve directly affects the flow capacity and pressure drop within the system. It's essential to measure the pipe diameter and consider the flow rate requirements of the application. A valve that is too small may create a bottleneck, risking inefficiency and potential damage; conversely, an oversized valve can lead to poor flow control and increased costs.

Pressure ratings are equally important when choosing a ball valve. Each valve is designed to operate within specific pressure limits, typically indicated by the manufacturer. Understanding the operational pressure of the system is vital for ensuring safety and longevity. Selecting a valve with an appropriate pressure rating helps prevent failures such as leaks or catastrophic ruptures. It's advisable to consider not only the maximum operating pressure but also potential pressure surges during operation. By carefully assessing both the size and pressure ratings, industrial facilities can ensure their ball valves perform effectively under the required conditions.

Selecting Appropriate Materials for Durability and Compatibility

When selecting the right ball valve for industrial applications, it is crucial to focus on the materials used in their construction to ensure both durability and compatibility with the system. The choice of materials directly influences the valve's resistance to environmental factors, such as temperature extremes, pressure variations, and exposure to corrosive substances. For instance, stainless steel is often favored for its strength and corrosion resistance, while PVC or CPVC might be selected for their lightweight properties and chemical compatibility.

Tips: Always consider the specific operational conditions of your system when choosing materials. Assess factors like the type of fluids passing through the valve, the operating temperature, and whether the environment is corrosive. Conducting a materials compatibility analysis can prevent costly failures and downtime.

Additionally, advancements in related technologies, such as those seen in flexible perovskite solar cells, highlight the importance of innovative materials in enhancing performance and functionality. Just as these solar cells are designed for optimal integration in self-powered systems, ball valves should also utilize cutting-edge materials that not only enhance durability but also promote seamless compatibility with modern industrial systems.

Tips: Utilize materials that support the integration of automation and advanced monitoring systems in your industrial application. This approach will not only enhance efficiency but also extend the lifespan of the equipment.

Assessing Cost and Maintenance Considerations for Your Operation

When selecting a ball valve for industrial applications, understanding cost and maintenance considerations is crucial for optimizing operation efficiency. The initial purchase price of a ball valve can vary significantly based on its material, size, and features. Industries often face the challenge of balancing upfront costs with long-term operational expenses. A higher-priced valve made from durable materials may reduce replacement frequency and downtime, thus proving more economical over time.

Maintenance is another essential factor to consider. Ball valves generally require less maintenance than other valve types due to their simple design and reliable sealing capabilities. However, periodic inspections and routine maintenance are necessary to ensure longevity and prevent leaks. Understanding the specific maintenance requirements associated with different types of ball valves can help companies plan their maintenance schedules effectively, reducing unforeseen costs and enhancing productivity. Evaluating both the financial implications and maintenance demands of ball valves will lead to more informed purchasing decisions that align with industrial needs.

Ball Valve Cost and Maintenance Analysis

Related Posts

-

The Future of Innovation in Ball Valve Technology

-

The Future of Quick And Easy Fittings: Revolutionizing Efficiency in Industrial Solutions

-

Understanding the Different Types of Compression Fittings in Plumbing

-

Understanding the Unique Features of Ball Valve Types for Industrial Applications

-

Discover Innovative Examples of Quick And Easy Fittings Solutions

-

7 Essential Tips for Sourcing High-Quality Brass Elbows in Today's Global Market