How to Choose the Right Compression Fittings for Your Plumbing Projects

When it comes to plumbing projects, selecting the right components is crucial for ensuring durability and efficiency, particularly when it involves Compression Fittings. According to a report by the National Association of Home Builders, improper fittings can lead to significant water wastage and costly repairs, with leaks accounting for over 14% of the average household's water usage. In fact, a study by the Environmental Protection Agency suggests that fixing leaks in plumbing can save homeowners approximately 10% on their water bills annually. With the growing emphasis on sustainability and efficiency in the plumbing industry, choosing quality compression fittings has become paramount. This blog will guide you through the essential factors to consider when selecting compression fittings for your plumbing projects, equipping you with the knowledge to make informed decisions that enhance both performance and reliability.

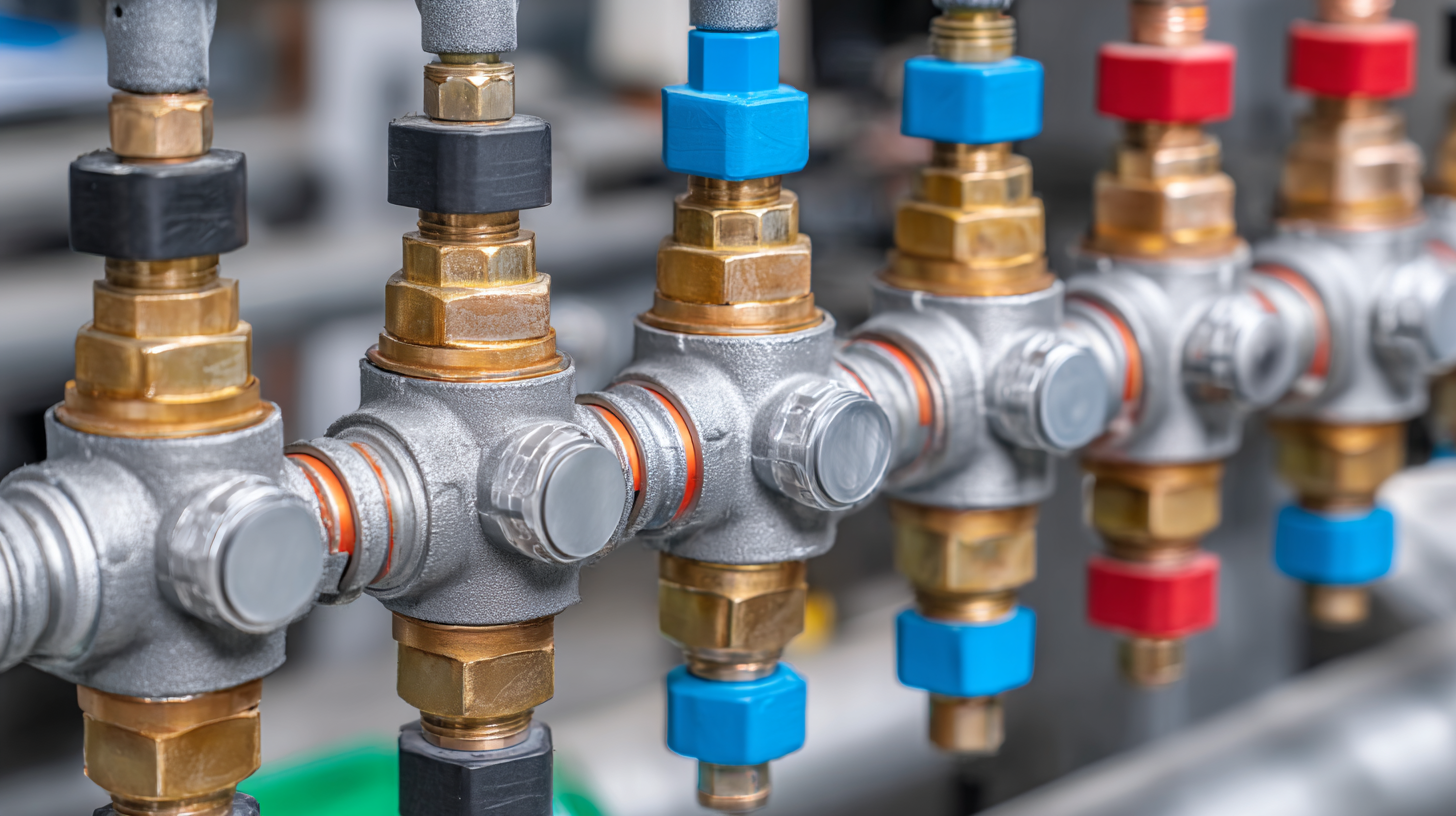

Understanding the Basics of Compression Fittings in Plumbing

Understanding compression fittings is essential for any plumbing project, as they provide a secure and reliable way to connect various types of piping. These fittings work by compressing a ring onto the pipe, creating a watertight seal. This technology is particularly beneficial in making connections with materials such as PEX tubing, which has become increasingly popular due to its flexibility and resistance to corrosion.

When working with PEX, it's important to follow proper procedures to ensure a strong connection. For example, when using press fittings, the first step is to cut the PEX tubing squarely. This ensures that the fitting can slide on easily and aligns correctly with the pipe. Once the fitting is in place, it is important to apply the appropriate pressure to secure the connection. Understanding these basics of compression fittings will help you select the right components for your plumbing projects, ultimately leading to efficient installations and long-lasting results.

Key Factors to Consider When Selecting Compression Fittings

Choosing the right compression fittings for plumbing projects can significantly impact the overall efficiency and safety of the system. When selecting these fittings, it's essential to consider key factors such as the type of material, pressure rating, and size compatibility. According to a report by the International Association of Plumbing and Mechanical Officials (IAPMO), using the correct fittings can reduce leak incidents by over 30%, emphasizing the importance of proper selection.

Tip: Always match the material of the compression fittings with the piping material to ensure a tight seal and avoid corrosion. For example, using brass fittings with copper pipes is a proven combination that offers durability and resistance to wear. Additionally, ensure that the fittings can handle the maximum pressure demands of your plumbing system, as mismatched ratings can lead to catastrophic failures.

Another critical consideration is the installation technique. A study from the American Society of Sanitary Engineering (ASSE) reveals that correct installation can extend the lifespan of compression fittings by up to 50%. Thus, taking the time to follow product guidelines and using appropriate tools is vital for achieving optimal performance and longevity.

Comparing Different Materials Used in Compression Fittings

When choosing compression fittings for plumbing projects, the material used is a critical factor that can significantly affect performance and longevity. Common materials include brass, plastic, and stainless steel, each offering distinct advantages and limitations. Brass is known for its strength and corrosion resistance, making it suitable for a wide variety of applications. On the other hand, plastic fittings are lightweight and resistant to chemicals, often making them ideal for low-pressure systems. Stainless steel fittings provide exceptional durability and is commonly used in applications where high pressure and temperature are factors.

Recent advances in material science shed light on how different materials perform under compression and other forces. For instance, studies on hydroxyapatite scaffolds reveal the importance of material composition and structural design in load-bearing applications. Similarly, research on polyamide-6 based foams and their compression behavior provides insights into how soft materials can be engineered for various mechanical properties. Understanding these material characteristics can guide plumbers in selecting the right compression fittings that not only match the specific requirements of their projects but also ensure reliable and efficient system performance.

Comparison of Different Materials Used in Compression Fittings

Common Mistakes to Avoid When Installing Compression Fittings

When installing compression fittings in your plumbing projects, it's crucial to steer clear of common pitfalls that can lead to leaks and costly repairs. One frequent mistake is failing to clean the pipe ends thoroughly before installation. Any debris, dirt, or old sealant can prevent a proper seal, causing water to leak at the connection. Always take the time to clean the surfaces thoroughly to ensure a tight fit.

Another common error is over-tightening the fittings. Many DIYers believe that tighter is always better, but excessive force can damage the fitting and create stress on the pipes. Instead, follow the manufacturer’s specifications for torque settings, which will help you achieve an optimal seal without compromising the integrity of the materials. Additionally, it’s important to align the fittings correctly; misalignment can lead to uneven pressure points, further increasing the chance of leaks. By avoiding these mistakes, you can enhance the durability and effectiveness of your plumbing system.

How to Choose the Right Compression Fittings for Your Plumbing Projects - Common Mistakes to Avoid When Installing Compression Fittings

| Fitting Type | Material | Common Uses | Size Range | Common Mistakes |

|---|---|---|---|---|

| Compression Elbow | Brass | Connecting pipe bends | 1/2" - 2" | Not using correct torque |

| Compression Coupling | Stainless Steel | Joining two pipes | 1/2" - 4" | Failing to clean pipe ends |

| Compression Tee | Plastic | Branching off a pipe | 3/4" - 2" | Ignoring system pressure |

| Compression Cap | Brass | Closing a pipe end | 1/2" - 2" | Not checking for leaks |

| Compression Adapter | Bronze | Changing pipe sizes | 1/2" - 3" | Using mismatched materials |

Maintenance Tips for Prolonging the Life of Your Compression Fittings

When it comes to plumbing projects, the longevity and reliability of compression fittings can significantly impact overall system performance. To ensure these fittings serve you well, regular maintenance is essential. According to industry reports, improper fitting care can lead to leaks or failures, creating costly repairs and downtime. Regularly inspecting your fittings for signs of corrosion or wear can help identify issues before they escalate, prolonging their life and maintaining system efficiency.

Incorporating best practices into your maintenance routine is vital. Ensure that fittings are not over-tightened, as this can cause damage or deformation. Instead, refer to manufacturer guidelines for torque specifications. Additionally, keeping the fittings clean and free of debris will prevent blockages and facilitate proper sealing.

Research indicates that fittings maintained under optimal conditions can have a lifespan of over 20 years, significantly reducing replacement frequency and costs. By prioritizing maintenance and adhering to best practices, you can safeguard the integrity of your plumbing projects and ensure smooth operation for years to come.

Related Posts

-

The Future of Best Compression Fittings Revolutionizing Global Supply Chains

-

How to Choose the Right Compression Fittings for Your Plumbing Needs

-

Understanding the Different Types of Compression Fittings in Plumbing

-

Understanding the Unique Features of Ball Valve Types for Industrial Applications

-

Quick And Easy Fittings: A Data-Driven Comparison of Efficiency and Cost-Effectiveness in Modern Manufacturing

-

The Future of Innovation in Ball Valve Technology