How to Choose the Right Compression Fittings for Your Global Procurement Needs

In today's increasingly interconnected global market, the demand for high-quality compression fittings has surged, driven by the expansion of industries such as oil and gas, water and wastewater management, and construction. According to a report from MarketsandMarkets, the global market for compression fittings is projected to reach USD 7.3 billion by 2025, growing at a CAGR of 6.2% from 2020 to 2025. This growth underscores the importance of selecting the right compression fittings to ensure efficiency and safety across various applications.

As businesses navigate the complexities of procurement, understanding the key factors that influence the selection of compression fittings—such as material compatibility, pressure ratings, and environmental considerations—becomes crucial for optimizing operational performance and achieving compliance with industry standards. This guide aims to equip procurement professionals with practical tips and insights to make informed decisions tailored to their specific needs.

Understanding the Basics of Compression Fittings and Their Applications

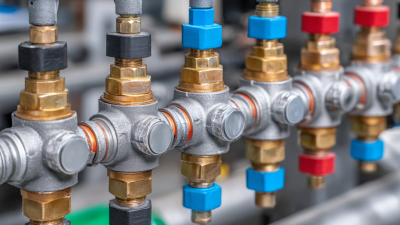

Compression fittings are essential components in various industrial applications, providing secure connections for pipes and tubing without the need for welding or threading. Understanding the basics of these fittings is crucial for global procurement needs. Compression fittings consist of several parts, including a nut, a ring (or ferrule), and a body, which work together to create a tight seal. This configuration allows for easy assembly and disassembly, making them ideal for applications in fluid and gas transport, particularly in sectors like oil and gas, water supply, and HVAC systems.

Recent advancements in materials science have contributed significantly to the performance and longevity of compression fittings. For instance, innovative materials that enhance durability and resistance to corrosion are now widely available, leading to extended service life and reduced maintenance costs. Data from industry reports indicate that the global market for compression fittings is projected to grow considerably, driven by increasing infrastructure development and the demand for efficient energy solutions. The integration of piezoelectric energy harvesting technologies in fluid systems also presents new opportunities for compression fittings, allowing for more sustainable and self-sufficient operations in various applications.

Key Factors to Consider When Selecting Compression Fittings Globally

When selecting compression fittings for global procurement, several critical factors must be considered to ensure compatibility and performance. First and foremost is the material composition of the fittings. Different applications may require specific materials, such as brass, stainless steel, or plastic, each offering unique properties like corrosion resistance and pressure tolerance. Understanding the environmental conditions of the installation site is essential; for instance, marine environments may necessitate more durable and resistant materials such as marine-grade stainless steel.

Another key factor is the size and compatibility of the fittings with existing systems. It is crucial to ensure that the dimensions match the specifications of the pipes and tubes being used to avoid leaks and maintain system integrity. Additionally, standards and certifications should be verified, as different regions may have varying regulations regarding pressure ratings and safety requirements. By keeping these considerations in mind, procurement professionals can make informed decisions that will lead to successful installations and long-lasting performance.

Material Compatibility: Choosing the Right Material for Your Fittings

When selecting compression fittings for global procurement, material compatibility is a crucial factor that can significantly affect performance and longevity. Various industries rely on specific materials to withstand environmental factors, pressures, and chemical exposures. For instance, according to a recent report by the Research Institute of Materials Technology, metallic fittings made from stainless steel are preferred in high-pressure applications due to their excellent corrosion resistance and strength, particularly in oil and gas sectors where chemical exposure is a concern.

In contrast, plastic fittings, such as those made from polypropylene or PVC, offer valuable benefits in plumbing and HVAC applications. A study published in the Journal of Polymer Science highlights that these materials are lightweight, cost-effective, and resistant to scale buildup, which can extend longevity and reduce maintenance costs. However, it's essential to recognize that using the wrong material can lead to catastrophic failure, as shown in data from the Global Pipe Survey, which recorded that improper material selection accounted for nearly 30% of pipeline failures in industrial settings. Thus, understanding the specific requirements of your application is key to ensuring both safety and efficiency in the long run.

How to Choose the Right Compression Fittings for Your Global Procurement Needs - Material Compatibility: Choosing the Right Material for Your Fittings

| Material Type | Temperature Range (°C) | Chemical Compatibility | Applications | Cost (per unit) |

|---|---|---|---|---|

| Brass | -40 to 150 | Excellent with water, air, and some fuels | Plumbing, HVAC systems | $0.50 |

| Stainless Steel | -100 to 400 | Excellent with corrosive materials | Food processing, chemical applications | $1.20 |

| PVC | -30 to 60 | Good with acids and soils | Irrigation systems, drainage | $0.30 |

| Copper | -50 to 200 | Good with water, limited with ammonia | Water supply, heating systems | $0.80 |

| Polypropylene | -20 to 90 | Good with acids, not good with hydrocarbons | Chemical transport, food applications | $0.25 |

Assessing the Quality Standards and Certifications for Compression Fittings

When selecting compression fittings for global procurement, understanding quality standards and certifications is crucial. Compression fittings are widely used in various industries, from plumbing to aerospace, making it imperative to ensure they meet stringent safety and performance criteria. Quality standards such as ISO 9001 indicate a manufacturer’s commitment to maintaining high-quality processes, while industry-specific certifications, like ASME for pressure vessels, ensure that the fittings can withstand specific operational pressures and environmental conditions.

Additionally, certifications from organizations such as the American National Standards Institute (ANSI) or Underwriters Laboratories (UL) can provide further assurance of quality and safety. These certifications often assess materials used, manufacturing processes, and testing protocols, ensuring that the fittings are not only reliable but also compliant with international regulations. By prioritizing suppliers with recognized certifications, procurement professionals can mitigate risks and enhance the overall integrity of their projects, ensuring they are equipped with fittings that will deliver long-lasting performance under demanding conditions.

Cost-Effectiveness vs. Quality: Making Smart Procurement Decisions

When it comes to global procurement of compression fittings, the balance between cost-effectiveness and quality is a critical consideration. Organizations often find themselves grappling with the allure of lower prices offered by various suppliers, but this approach can compromise the reliability and longevity of the fittings. High-quality compression fittings, while they might initially require a larger investment, typically offer better performance, reduced maintenance costs, and longer service life. Therefore, it is crucial to evaluate not only the price of the fittings but also the potential hidden costs that come with inferior products.

Furthermore, understanding the specific application requirements is essential in making smart procurement decisions. Different industries and projects may demand varying specifications and materials that can impact both the performance and the overall cost. For instance, selecting a fitting designed for high-pressure environments can significantly reduce the risk of leaks and failures, despite a higher upfront cost. By investing in quality materials that meet stringent industry standards, organizations can ensure safety and efficiency, ultimately leading to better financial outcomes in the long run. Prioritizing quality may initially seem expensive, but it often proves to be the more economical choice when considering the full lifecycle of the products.

Related Posts

-

How to Choose the Right Compression Fittings for Your Plumbing Projects

-

The Future of Best Compression Fittings Revolutionizing Global Supply Chains

-

How to Choose the Right Compression Fittings for Your Plumbing Needs

-

Understanding the Different Types of Compression Fittings in Plumbing

-

5 Essential Tips for Choosing Quick And Easy Fittings for Your Projects

-

7 Essential Tips for Sourcing High-Quality Brass Elbows in Today's Global Market