Understanding the Different Types of Compression Fittings in Plumbing

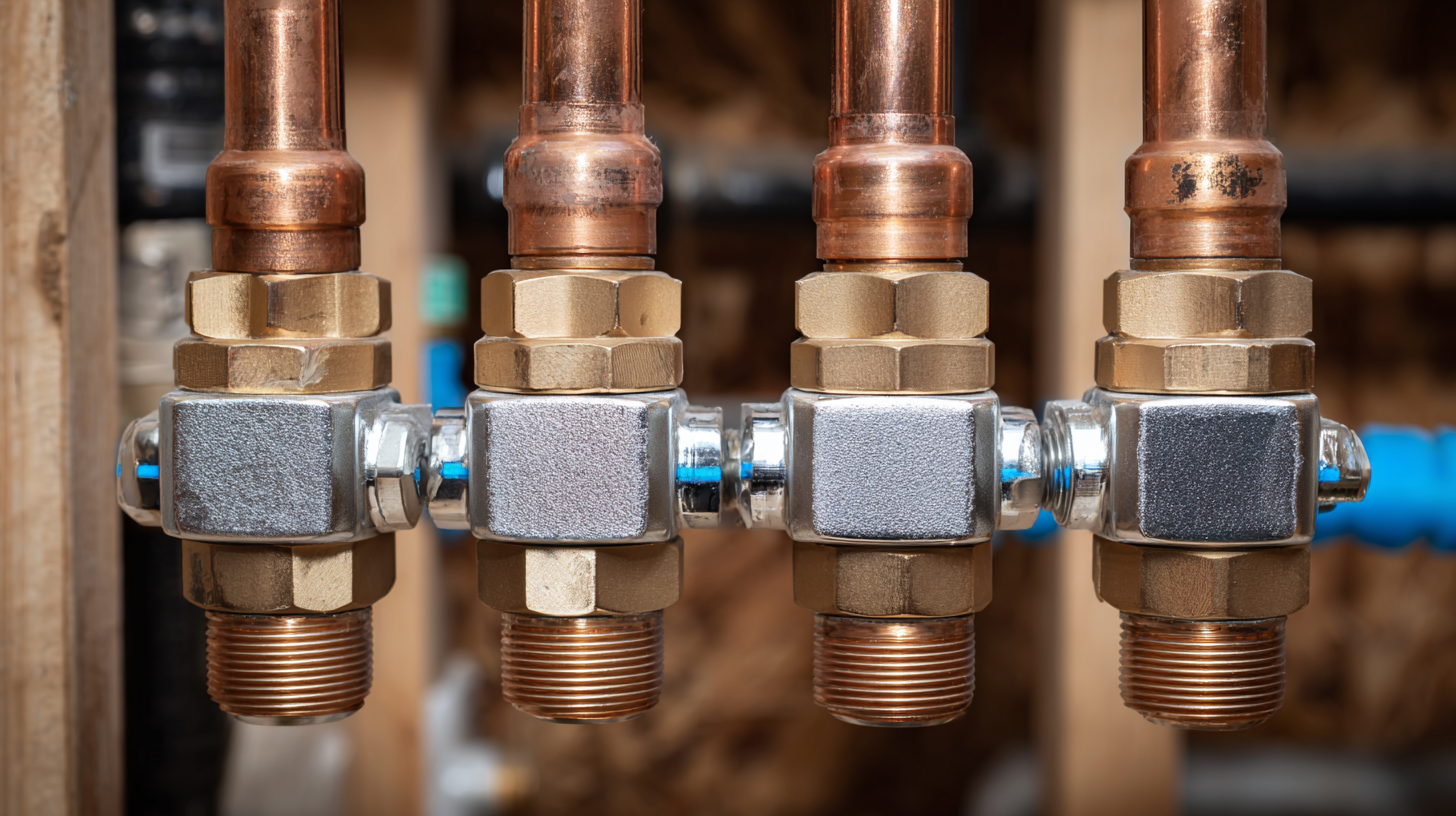

In the realm of plumbing, understanding the various types of compression fittings is crucial for both professionals and DIY enthusiasts. Compression fittings play a vital role in creating secure connections between pipes, ensuring leak-free performance in a variety of systems. These fittings are designed to join two or more pipes securely without the need for welding or soldering, making them an ideal choice for many plumbing applications. With different types available, from straight couplings to elbow fittings, each serves a unique purpose tailored to specific plumbing needs. In this article, we will delve into the different types of compression fittings, their applications, and how to select the appropriate fitting for your plumbing project, ensuring that you have the knowledge needed to make informed decisions.

Exploring the Basics of Compression Fittings: What You Need to Know

Compression fittings are essential components in plumbing systems, designed to connect two pipes or tubes securely without the need for soldering or welding. These fittings work by compressing a ferrule onto the pipe, creating a watertight seal that is both reliable and easy to install. Understanding the basics of compression fittings can save you time and potential leaks in your plumbing projects.

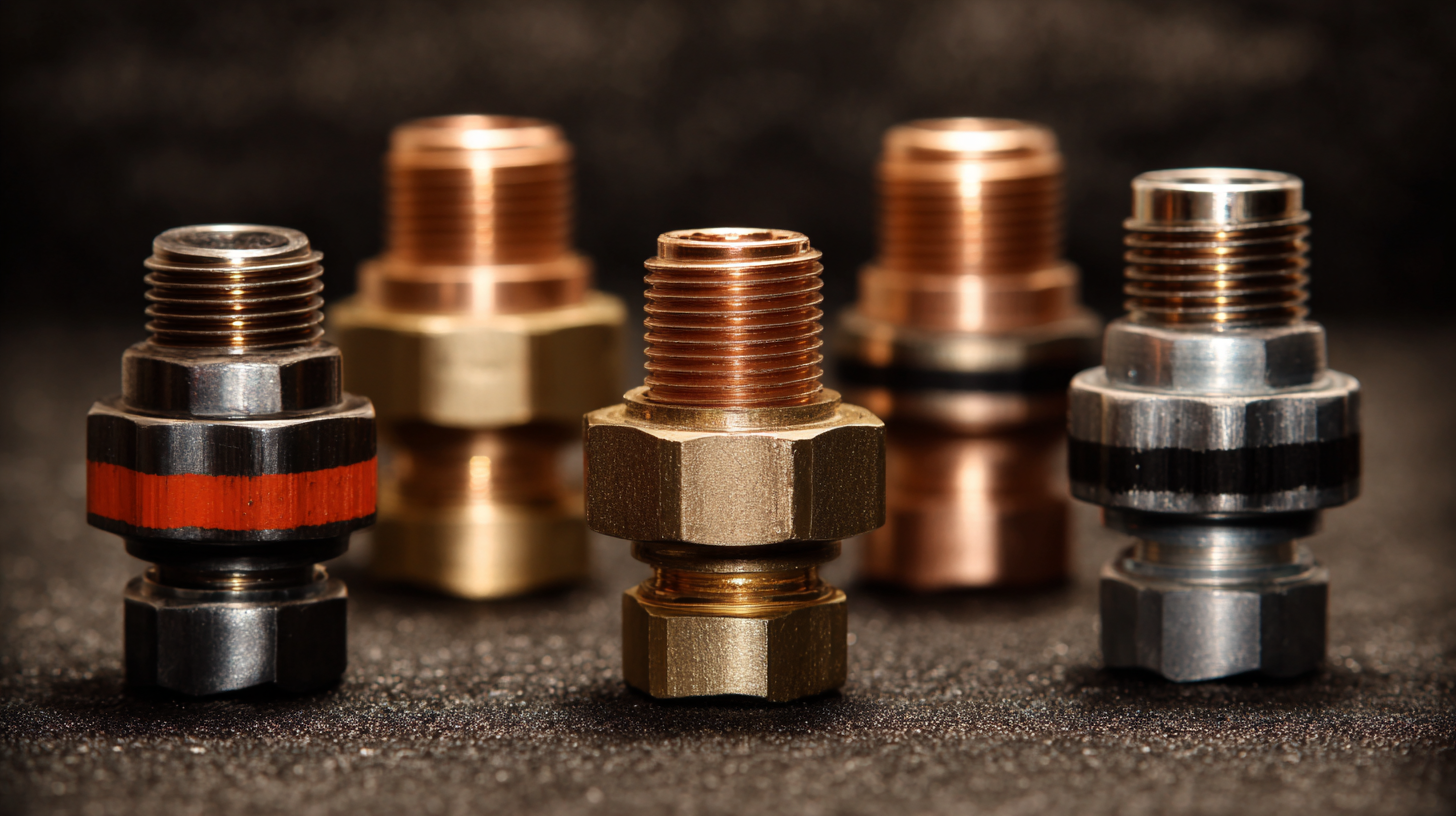

When choosing compression fittings, it's important to pay attention to the material compatibility. Common materials include brass, copper, and plastic. Brass fittings, for instance, are known for their durability and resistance to corrosion, making them suitable for various applications. Tips for installation include ensuring that the pipe is cut cleanly and squarely, which helps achieve a better seal. Additionally, be mindful not to overtighten the fittings, as this can lead to damage and leaks.

Another useful tip is to use a pipe joint compound or Teflon tape on the threads to enhance the seal and prevent leaks. Regular inspections of your compression fittings are also wise, as over time, the joints can wear or corrode, potentially leading to water damage. By understanding the basics and following these tips, you can ensure that your plumbing systems remain leak-free and functional for years to come.

Understanding the Different Types of Compression Fittings in Plumbing

| Type of Compression Fitting | Material | Application | Advantages |

|---|---|---|---|

| Straight Compression Fittings | Brass, Copper | Joining two pipes of the same diameter | Simple design, easy to install |

| Elbow Compression Fittings | Brass, Plastic | Changing the direction of flow | Reduces the need for multiple fittings |

| Tee Compression Fittings | Brass, Copper | Branching off a main line | Allows for additional outlets |

| Reducing Compression Fittings | Brass, Copper | Connecting pipes with different diameters | Versatile, helps in adapting sizes |

| Cap Compression Fittings | Brass, Plastic | Sealing the end of a pipe | Prevents leakage |

Types of Compression Fittings: A Comprehensive Overview

Compression fittings play a crucial role in plumbing systems, serving as essential connectors for pipes of various materials. Their primary function is to create a secure, leak-proof seal that facilitates fluid transport while accommodating slight variations in pipe diameter and alignment. The different types of compression fittings include brass, plastic, and stainless steel options, each chosen based on specific application needs and environmental conditions. According to industry reports, metal fittings account for approximately 60% of the global market, driven by their durability and resistance to corrosion.

Another notable aspect of compression fittings is their ease of installation. Unlike soldering or welding, which require specialized skills and equipment, compression fittings can be installed quickly with basic tools, reducing labor costs significantly. A comprehensive analysis of plumbing supply chains indicates that the demand for compression fittings is expected to grow by 4.5% annually, particularly in regions experiencing rapid urban development. This growth underscores the importance of understanding the various types of compression fittings available, as selecting the right fitting can enhance system efficiency and longevity, making it essential for both contractors and DIY enthusiasts.

Advantages of Using Compression Fittings in Plumbing Projects

Compression fittings are an essential component in plumbing, offering several advantages that make them a popular choice among professionals and DIY enthusiasts alike. One of the primary benefits of using compression fittings is their ease of installation. Unlike soldered joints that require extensive tools and skills, compression fittings can be quickly assembled using just a wrench and a few simple parts. This not only speeds up the installation process but also reduces the likelihood of errors, making it accessible for inexperienced installers.

Another significant advantage is their versatility. Compression fittings can be used with various pipe materials, including copper, plastic, and steel, making them suitable for a wide range of plumbing applications. Furthermore, they provide a reliable seal that can withstand high pressures, ensuring that leaks are minimized. This reliability is particularly important in plumbing projects where water supply lines need to maintain consistent pressure without risk of failure. Overall, the benefits of compression fittings in plumbing projects highlight their essential role in creating efficient and durable plumbing systems.

Installation Tips and Best Practices for Compression Fittings

When it comes to installing compression fittings in plumbing, several best practices can help ensure a leak-free and durable connection. First, proper surface preparation is crucial. Before starting the installation, make sure the pipe ends are clean and free from any debris, dirt, or old sealant. Using a pipe cutter for a clean, square cut will promote a better seal than using a hacksaw, which may create burrs on the pipe's edges.

During installation, it's important to hand-tighten the compression nut first to ensure that the fitting is in the correct position without cross-threading. After hand-tightening, use a wrench for snugging it further, but be cautious not to overtighten, as this can lead to damage or deformation of the fitting. It's also advisable to visually check the alignment of the fittings before and during the tightening process to make sure everything remains properly aligned.

Finally, after the installation, always test the system under pressure to check for any leaks, allowing you to address any issues before completing the project.

Common Issues and Troubleshooting with Compression Fittings

Compression fittings are widely used in plumbing due to their simplicity and reliability, but they can come with their own set of common issues. A report by the American Society of Plumbing Engineers highlights that nearly 30% of plumbing failures can be traced back to improper installation or maintenance of compression fittings. This statistic emphasizes the importance of understanding the components and potential pitfalls associated with these fittings.

One of the most frequent problems is leaking, often caused by inadequate tightening or wear and tear over time. A study from the Plumbing Manufacturers International indicates that leaks from compression fittings can lead to water loss averaging 2,000 gallons per year per household. Additionally, corrosion from corrosive water can weaken the compression collar, exacerbating the issue. Regular inspection and timely replacement can prevent these leaks, saving both water and cost in the long run.

Another issue is the risk of over-tightening, which can damage the fitting itself. The same PMI study notes that 25% of fittings fail due to over-torquing, leading to cracks and eventual failure. Thus, proper installation techniques and the use of torque wrenches can help mitigate these risks, ensuring that compression fittings serve their intended purpose without causing significant issues in your plumbing system.

Related Posts

-

How to Choose the Right Compression Fittings for Your Plumbing Needs

-

Understanding the Challenges with Ppsu Pex Fittings in Modern Plumbing Solutions

-

7 Essential Tips for Sourcing High-Quality Brass Elbows in Today's Global Market

-

The Ultimate Guide to Choosing the Right Stainless Steel Pipe Fittings for Your Projects

-

The Future of Quick And Easy Fittings: Revolutionizing Efficiency in Industrial Solutions

-

How to Select the Best OEM Precision Parts for Your Manufacturing Needs