Understanding the Role of OEM Precision Parts in Modern Manufacturing: Innovations and Impacts

In today's rapidly evolving manufacturing landscape, the role of OEM precision parts has become increasingly significant, driving innovations and efficiency across industries. A report by MarketsandMarkets projects that the global market for precision parts will reach USD 2.45 trillion by 2025, highlighting the growing demand for high-quality components. The integration of advanced technologies such as automation and IoT has further transformed the production processes, allowing manufacturers to achieve unprecedented precision and customization. Manufacturers that utilize OEM precision parts can ensure not only compliance with stringent industry standards but also enhance product performance and reliability. As companies strive for competitive advantage, understanding the pivotal role of OEM precision parts in modern manufacturing is essential for fostering innovation, reducing costs, and meeting the diverse needs of consumers in a dynamic marketplace.

The Significance of OEM Precision Parts in Today's Manufacturing Landscape

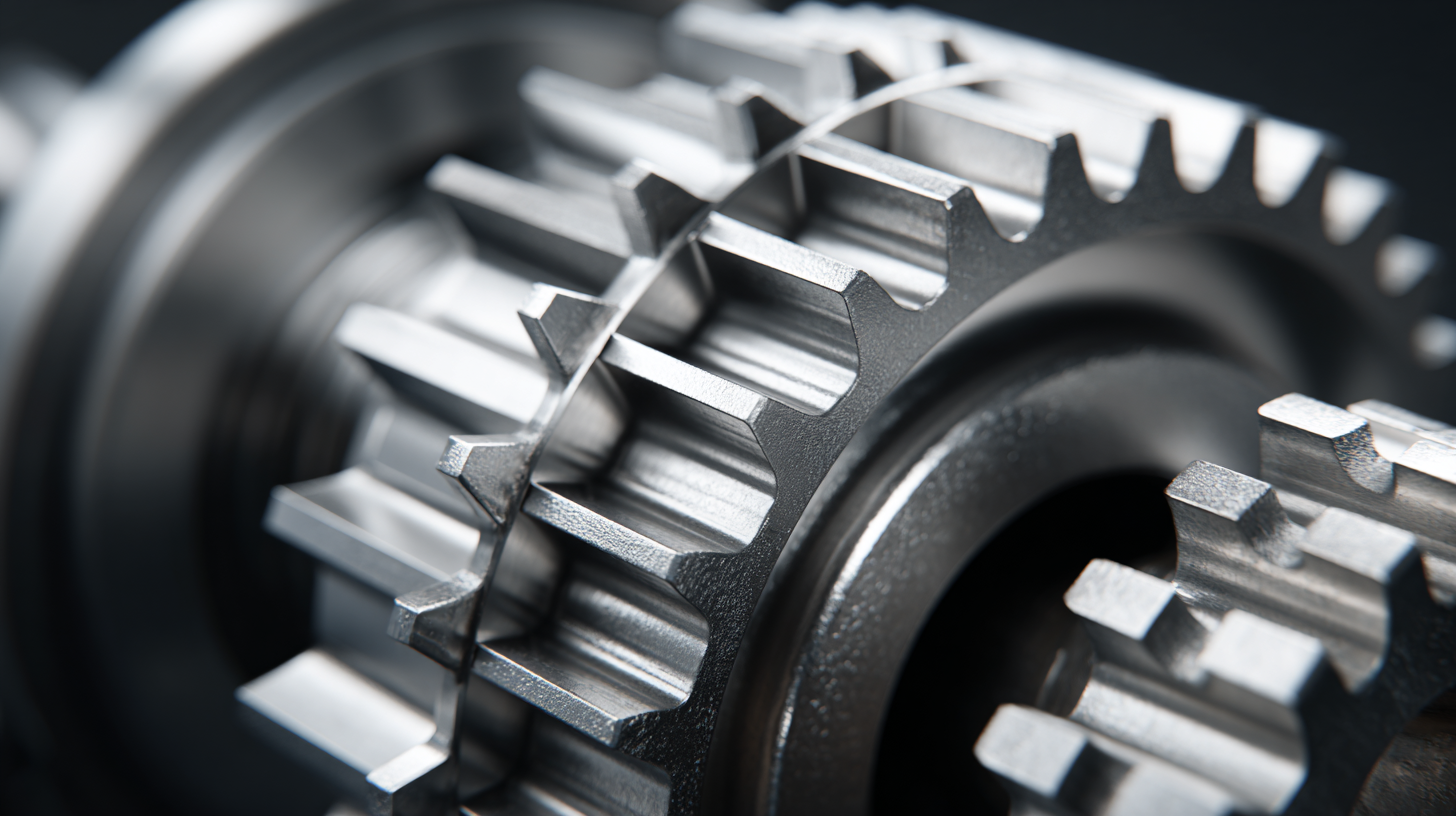

OEM precision parts play a vital role in the contemporary manufacturing landscape, characterized by an increasing demand for performance, efficiency, and reliability. According to a report by MarketsandMarkets, the global market for OEM services is projected to reach USD 700 billion by 2026, growing at a CAGR of 5.2% from 2021. This growth reflects the expanding reliance on tailored parts that meet specific technical specifications, highlighting the importance of precision in meeting modern manufacturing standards.

In various industries such as automotive, aerospace, and electronics, the integration of high-quality OEM precision parts enhances not only the functionality and durability of products but also streamlines production processes. A study by Grand View Research indicates that precision components reduce waste and increase production yield by as much as 30%. The robust performance of OEM parts leads to lower maintenance costs and enhances overall operational efficiency, proving indispensable in today’s highly competitive manufacturing environment. As manufacturers continue to innovate, the use of precision-engineered OEM parts will significantly influence productivity and product quality across the board.

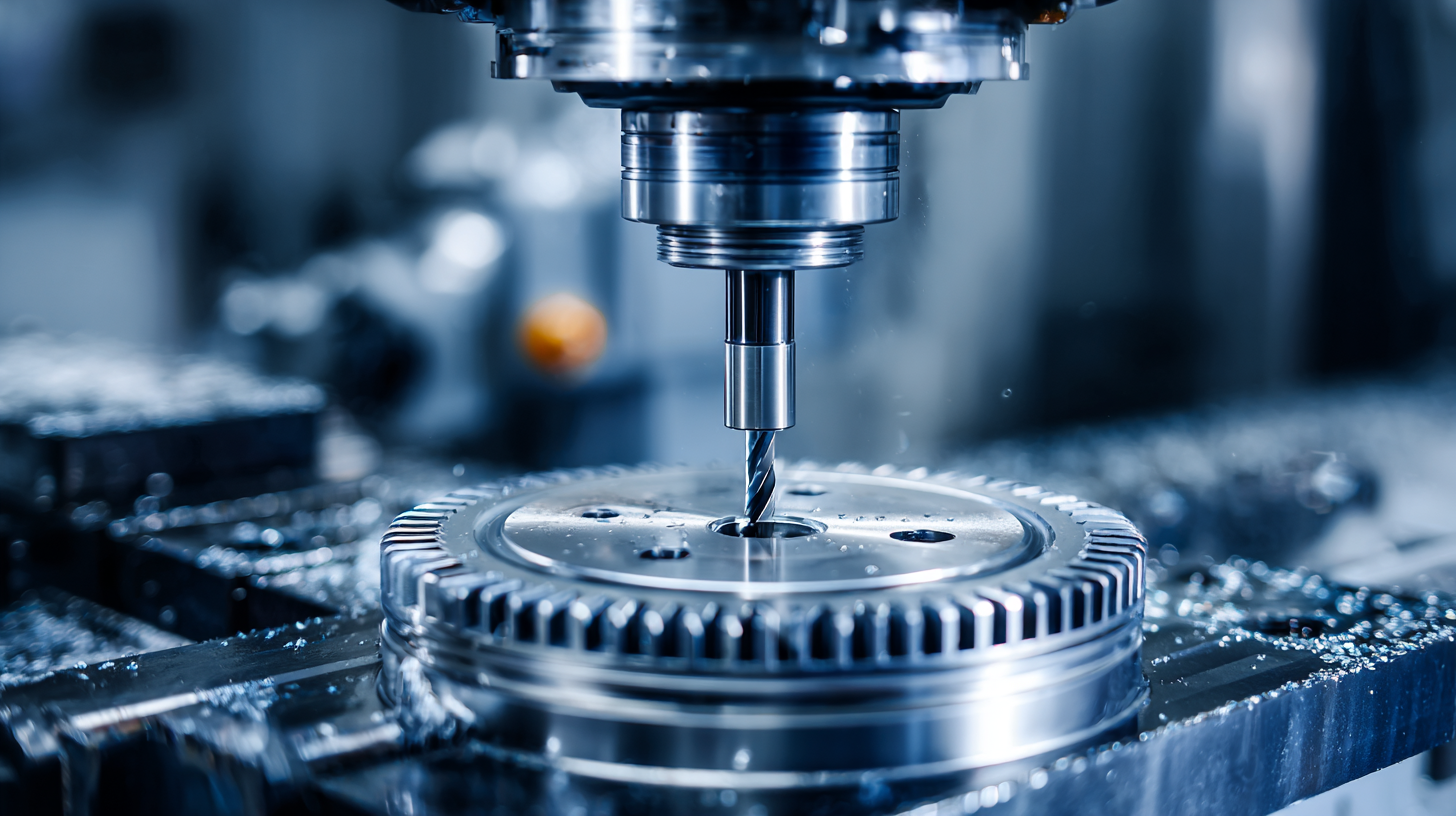

Technological Innovations Shaping the Future of OEM Components

In the rapidly evolving landscape of modern manufacturing, technological innovations are significantly shaping the future of OEM (Original Equipment Manufacturer) components. According to a recent report by MarketsandMarkets, the global OEM parts market is projected to reach $500 billion by 2026, growing at a compound annual growth rate (CAGR) of 8.5%. This growth is largely driven by advancements in manufacturing technologies such as additive manufacturing, automation, and Industry 4.0 implementations, which enable manufacturers to produce high-precision parts with reduced lead times and lower costs.

One transformative innovation is the adoption of smart manufacturing technologies, which integrate IoT (Internet of Things) sensors and artificial intelligence into production processes. A study by Deloitte highlights that leveraging these technologies can enhance production efficiency by up to 30%. Moreover, the use of data analytics allows manufacturers to predict maintenance needs and optimize inventory management, ensuring a seamless supply chain. These technological advancements not only improve the quality of OEM components but also provide manufacturers with a competitive edge in a global market increasingly focused on precision and reliability.

Impact of OEM Precision Parts on Supply Chain Efficiency

In the realm of modern manufacturing, OEM precision parts play a pivotal role in enhancing supply chain efficiency. According to a report by the International Production and Processing Expo, the adoption of OEM precision components can lead to a 20-30% reduction in production lead times, primarily due to their high compatibility and reliability. This efficiency not only streamlines production processes but also minimizes downtime, allowing manufacturers to quickly respond to market demands.

Furthermore, a study by the Manufacturing Institute indicates that businesses utilizing OEM parts experience a 15% decrease in inventory costs due to better forecasting and reduced waste. The standardization of parts from original equipment manufacturers means less variety in inventory, thus leading to easier management and significant cost savings. As industries increasingly focus on lean manufacturing practices, the integration of OEM precision parts emerges as a strategic move to bolster supply chain resilience and responsiveness, ensuring that manufacturers can keep pace in a rapidly evolving market environment.

Understanding the Role of OEM Precision Parts in Modern Manufacturing: Innovations and Impacts - Impact of OEM Precision Parts on Supply Chain Efficiency

| Parameter | Value | Impact Description |

|---|---|---|

| Lead Time Reduction | 25% | Faster delivery of precision parts enhances production timelines. |

| Defect Rate | 2% | Higher precision means lower defect rates in final products. |

| Cost Efficiency | 15% cost savings | Reduced waste and efficient manufacturing processes lead to lower costs. |

| Inventory Turnover | 30% | Improved parts availability leads to better inventory management. |

| Supplier Lead Time | 10 Days | Streamlined processes enable suppliers to deliver parts more quickly. |

Sustainability Trends in OEM Manufacturing Processes

The growing emphasis on sustainability within OEM manufacturing processes is reshaping the landscape of modern manufacturing. According to a recent report from the International Organization for Standardization (ISO), 62% of manufacturers are actively seeking to integrate sustainable practices in their operations. This shift is driven by an increasing demand from consumers for eco-friendly products, as well as regulatory pressures that encourage companies to reduce their carbon footprints. Innovations such as additive manufacturing, which can reduce waste material by up to 90%, are becoming key components in achieving these sustainability goals.

Moreover, advancements in materials science enable the development of precision parts that not only enhance product performance but also promote recyclability and lower environmental impacts. A study by the Ellen MacArthur Foundation highlights that transitioning to circular manufacturing models could unlock $4.5 trillion in economic benefits by 2030, illustrating the financial incentives for OEMs to adopt sustainable practices. By employing efficient supply chain strategies and investing in green technologies, manufacturers can significantly mitigate their impact on the environment while simultaneously meeting the demands of a more conscious consumer base.

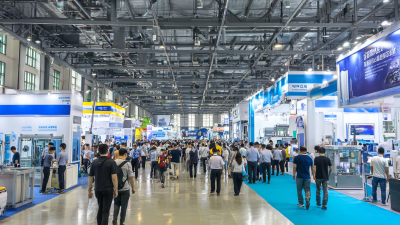

Challenges and Opportunities in the OEM Precision Parts Market

In the ever-evolving landscape of modern manufacturing, OEM precision parts play a critical role in ensuring efficiency and quality. However, the OEM precision parts market faces a myriad of challenges, such as rising material costs, stringent regulatory standards, and supply chain disruptions. Manufacturers must adapt to these hurdles while maintaining competitiveness and innovation in their product offerings.

**Tip:** Staying updated on material technologies and market trends can help manufacturers reduce costs and enhance product performance. Networking with industry peers and participating in trade shows may also unveil best practices and solution strategies.

On the flip side, there are significant opportunities in the OEM precision parts market. The growing demand for automation, coupled with advancements in manufacturing technologies like 3D printing and precision machining, presents avenues for manufacturers to innovate. By embracing digital transformation, manufacturers can enhance their production capabilities, improve product customization, and respond more effectively to market needs.

**Tip:** Investing in smart manufacturing technologies can lead to improved efficiency and operational excellence. Regular training for staff on new technologies will ensure that teams can leverage these advancements to maximize production efficacy.

Related Posts

-

Explore Business Opportunities in Oem Precision Parts at 2025 China 138th Import and Export Fair

-

The Ultimate Guide to Sourcing High-Quality Brass Fittings for Your Business Needs

-

Discover Exceptional PPSU PEX Fittings from Leading Chinese Manufacturers for Global Procurement

-

7 Essential Tips for Sourcing High-Quality Brass Elbows in Today's Global Market

-

Understanding the Unique Features of Ball Valve Types for Industrial Applications

-

Ensuring Excellence in Manufacturing Standards for Best Ppsu Pex Fittings