The Ultimate Guide to Press Fittings: Transforming Plumbing with Innovative Connections

As the plumbing industry continues to evolve, the adoption of Press Fittings has emerged as a transformative solution that is reshaping how professionals approach piping connections. According to recent industry reports, the global market for press fittings is projected to grow at a compound annual growth rate (CAGR) of 6.5% from 2021 to 2028, driven by increasing demand for efficient installation techniques and reliable leak-proof connections. Press fittings not only reduce installation time by up to 50% compared to traditional welding methods but also enhance the overall durability and longevity of plumbing systems. By leveraging advanced technologies and materials, press fittings are not just a passing trend; they represent a significant leap forward in plumbing innovation, making them an indispensable tool for modern contractors and engineers. This guide aims to delve into the numerous advantages of press fittings, offering practical tips and insights to help professionals maximize their application in various plumbing projects.

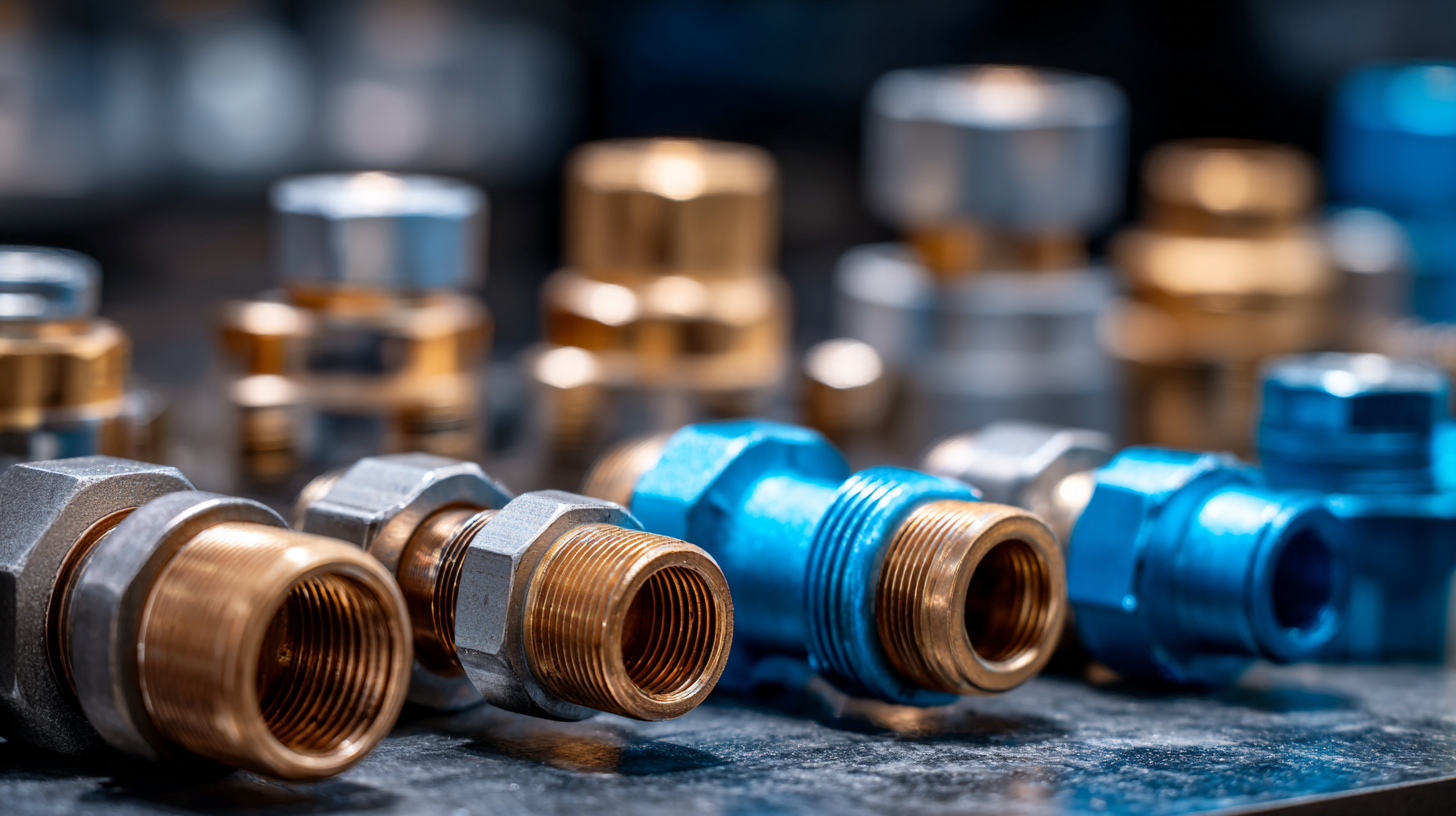

Understanding Press Fittings: Types and Applications in Modern Plumbing

Press fittings have revolutionized plumbing by offering efficient and reliable connections, eliminating the need for traditional soldering or welding techniques. According to the International Association of Plumbing and Mechanical Officials (IAPMO), the use of press fittings has seen a significant increase, with a projected annual growth rate of 7.1% from 2021 to 2028. This growth is largely attributed to the benefits of speed, safety, and reduced labor costs associated with press fitting installation.

There are several types of press fittings—such as copper, stainless steel, and PEX—each catering to specific applications in modern plumbing. The Copper Development Association reports that copper press fittings are especially popular in commercial applications due to their durability and resistance to corrosion. Additionally, a study by the Water Research Foundation indicates that using PEX press fittings can reduce installation time by up to 60%, making them a favorable choice in residential plumbing. The versatility and efficiency of press fittings thus position them as a smart solution for contemporary plumbing needs.

Essential Tools and Equipment for Installing Press Fittings Effectively

The installation of press fittings has revolutionized plumbing systems, providing quicker and more reliable connections compared to traditional methods. To effectively install these innovative fittings, having the right tools and equipment is paramount. Essential tools include a compact press tool, specifically designed for various fitting sizes, and a range of jaws corresponding to the fixtures you intend to install. According to a report by the International Association of Plumbing and Mechanical Officials (IAPMO), using press-fitting technology can reduce installation time by up to 50%, showcasing its efficiency in modern plumbing.

To ensure optimal performance during installation, it’s crucial to check compatibility between the fittings and the press tool. Make use of a torque wrench to maintain proper pressure without damaging the fittings. Additionally, investing in a quality pipe cutter can guarantee clean cuts, which is essential for a secure seal.

**Tips:** Always begin by cleaning the pipes thoroughly to remove any debris, as even small particles can compromise the integrity of the connection. Moreover, make sure to perform a pressure test post-installation to confirm that the fittings are secure and there are no leaks.

The Ultimate Guide to Press Fittings: Transforming Plumbing with Innovative Connections

| Dimension | Data |

|---|---|

| Material Types | Copper, Stainless Steel, PEX |

| Applications | Residential, Commercial, Industrial |

| Typical Sizes | 1/2", 3/4", 1" |

| Installation Tools | Press Tool, Pipe Cutter, Deburring Tool |

| Pressure Ratings | Up to 500 PSI |

| Advantages | Quick Installation, No Flame Required, Reliable Sealing |

| Maintenance | Minimal; Sleeves rarely need replacement |

Step-by-Step Guide to Properly Installing Press Fittings

Installing press fittings is a practical skill that can completely transform your plumbing projects. This step-by-step guide will take you through the process to ensure that you execute the installation correctly and efficiently.

Start by gathering the necessary tools, including a pressing tool, press fittings, and a pipe cutter. Before making any connections, be sure to prepare the pipe by cleaning the ends and checking for any damage. Measure and cut the pipe to the required lengths, ensuring that the cuts are straight for a proper seal. Once prepared, simply slide the press fitting onto the pipe until it is fully seated.

Next, use the pressing tool to compress the fitting securely onto the pipe. It’s crucial to follow the manufacturer's instructions regarding the pressure settings for your specific fittings. After pressing, inspect the connections for any leaks by performing a water test. This straightforward installation method not only enhances the reliability of your plumbing system but also saves you time and effort compared to traditional soldering techniques.

Common Mistakes to Avoid When Using Press Fittings in Plumbing

When using press fittings in plumbing, even seasoned professionals can fall into certain pitfalls that may compromise the integrity of the installation. Common mistakes include inadequate preparation of the pipe surface, failing to check for proper alignment, and overlooking the importance of using compatible fittings. According to industry reports, improper installation can lead to leaks that not only cause expensive repairs but also waste significant amounts of water, impacting both the environment and your utility bills.

**Tips:** Always ensure the pipe is clean and free from debris before making a connection. A clean surface allows the press fitting to create a solid seal, which is crucial to prevent leaks. Additionally, regularly inspecting your work for alignment can save you from future plumbing disasters—misalignment can put unnecessary stress on the fittings.

Another critical but commonly overlooked mistake is neglecting to read the manufacturer’s specifications. Adjusting your techniques according to these guidelines can significantly reduce the risk of errors. Failing to do so might invalidate warranties and lead to costly replacements. Stay informed and proactive to ensure your plumbing projects are successful with press fittings.

Maintaining and Troubleshooting Press Fittings for Long-lasting Performance

Maintaining and troubleshooting press fittings is crucial for ensuring long-lasting performance in plumbing systems. These innovative connections, designed for speed and reliability, require regular inspections to prevent leaks and ensure optimal functionality. From checking the sealing elements to monitoring for signs of wear, proactive maintenance can extend the lifespan of press fittings significantly.

Tips for maintaining your press fittings include regularly inspecting the fittings for any visible signs of corrosion or damage. Utilizing a torque wrench during installation can help ensure that connections are secure without being over-tightened, which could compromise the seals. Additionally, keeping the fittings and surrounding areas clean can help detect potential leaks early, allowing for timely repairs and preventing further issues.

When troubleshooting, it’s essential to use the right tools and techniques. Start by isolating the section of piping and conducting pressure tests to pinpoint leaks. If a fitting appears to be faulty, don’t hesitate to disassemble and inspect the internal components, as debris or improper sealing can often be the root cause. By staying vigilant and adopting these practices, you can ensure your plumbing system remains robust and efficient.

Related Posts

-

Exploring the Benefits of Compression Fittings for DIY Home Plumbing Projects

-

Ultimate Guide to Choosing the Right Press Fittings for Your Plumbing Needs

-

Discover Exceptional PPSU PEX Fittings from Leading Chinese Manufacturers for Global Procurement

-

How to Choose the Right Ball Valve for Your Industrial Needs

-

Quick And Easy Fittings: A Data-Driven Comparison of Efficiency and Cost-Effectiveness in Modern Manufacturing

-

Understanding the Challenges with Ppsu Pex Fittings in Modern Plumbing Solutions